Your Trustworthy Electronic Manufacturing Service

LHD Technology has PCB and SMT factories, providing design, reverse engineering, components and one-stop assembly services to help you save worry, trouble and cost.

- 22 years of stable professional foreign trade factory

- Professional sales engineer 1V1

- Permanent after-sales service

- Customer interests first

- No risk and capital security

- No MOQ

Quality-oriented

We insist on higher quality than our peers to ensure product stability and reliability.

Service First

Service is the branch and leaf of LHD, serving customers in all aspects and never ending

Integrity Cooperation

Cooperate with customers based on the principles of integrity and transparency.

Please Choose The Competitive Products!

Compared to most other suppliers, we only focus on service and satisfying any of your needs.

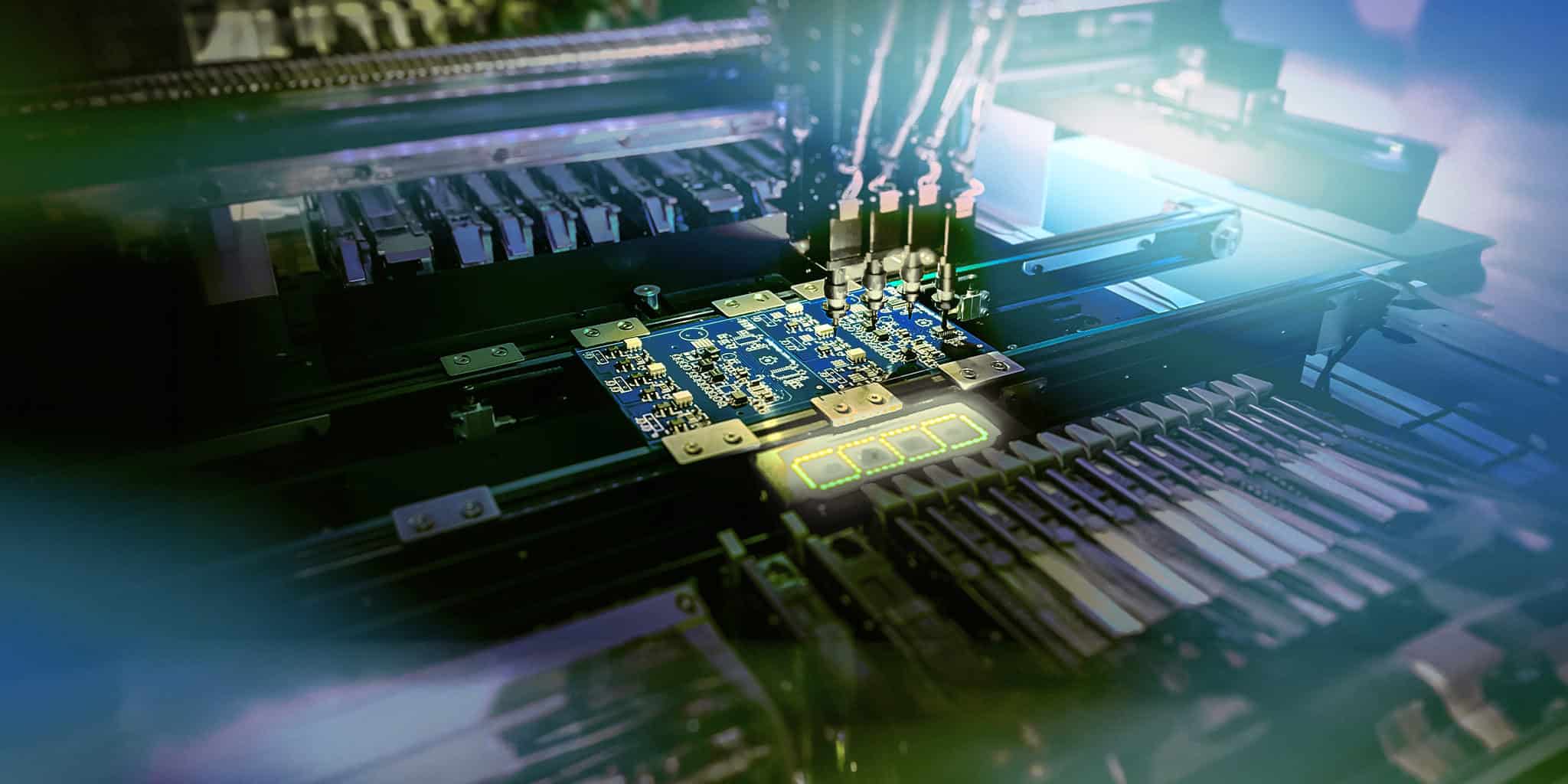

Provide seven advanced production lines to complete your BGA project

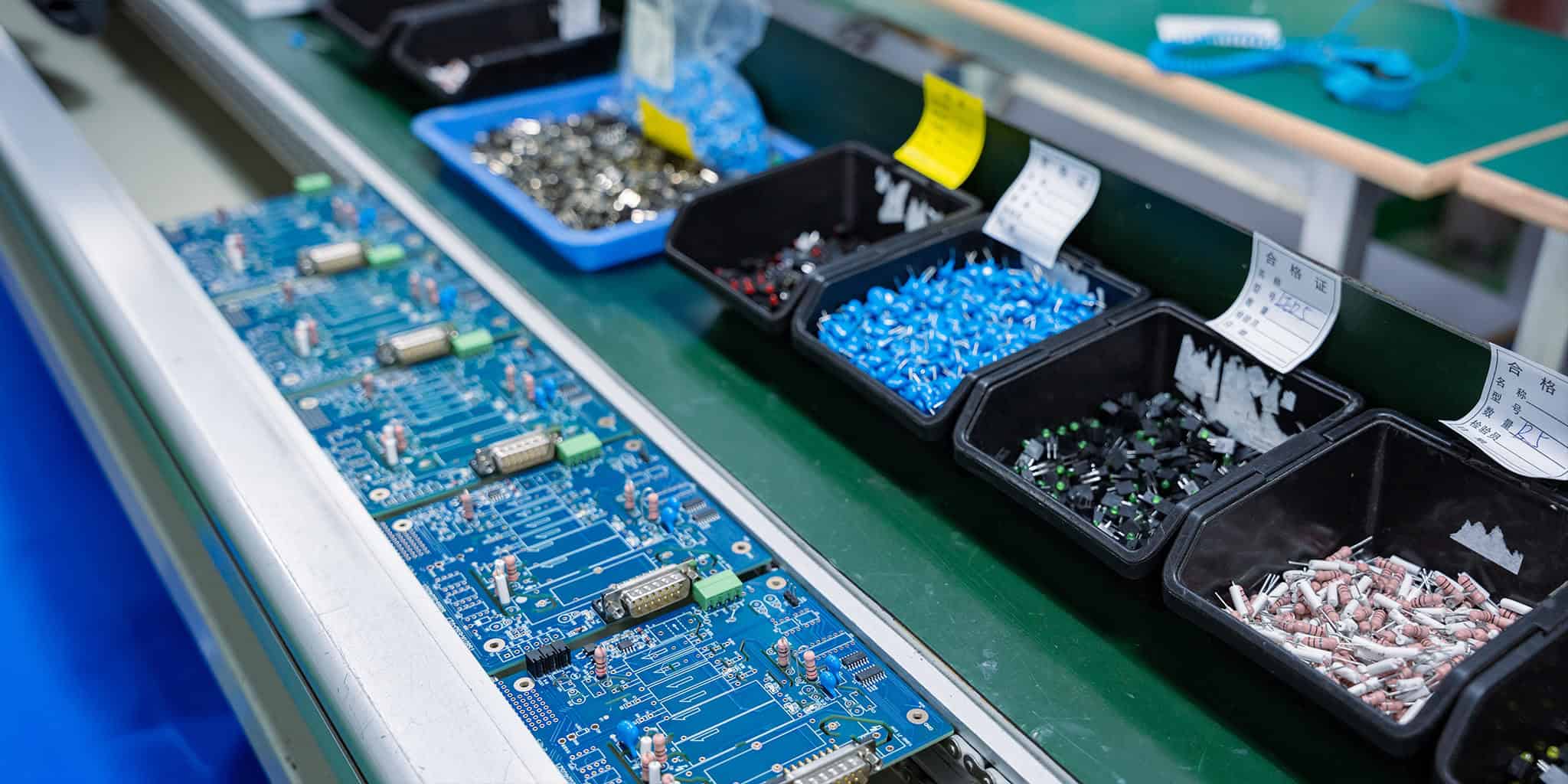

Explore More SolutionsProvide professional group manual plug-in to check the quality of each board

Explore More SolutionsProvide a complete and mature rapid prototyping supply chain

Explore More SolutionsProvide the most advanced equipment to ensure the quality of the project

Explore More SolutionsLHD One-Stop Service

Save Cost,Save Worry, Save Trouble

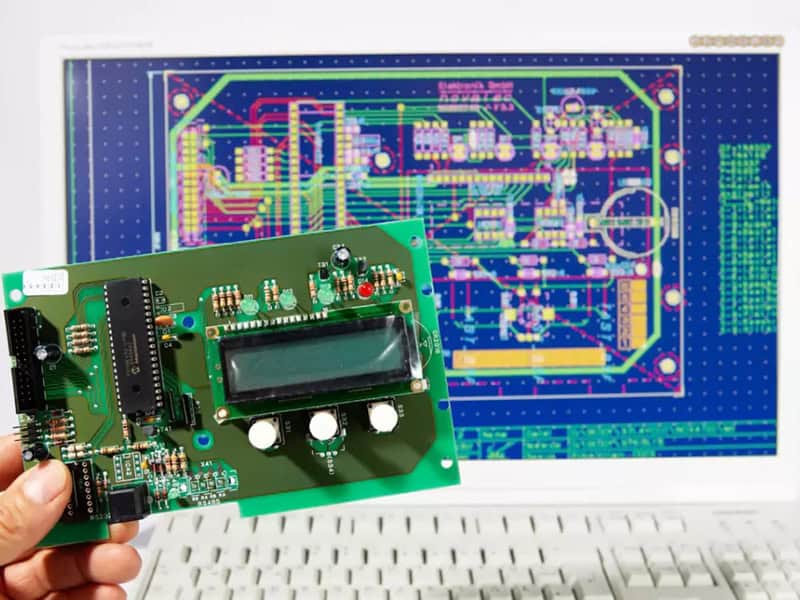

R&D Capability

• Circuit design

• PCB design

• Reverse engineering

• Embedded system development (MCU, ARM, FPGA)

• DFM

• Testing and verification

Experience-Team

• Industry knowledge and technical understanding

• Customer needs analysis and solutions

• Skills and negotiation

• Data analysis and goal management

• Teamwork and learning

• Customer service and after-sales support

Price

• Supply chain integration and optimization

• Cost control and lean management

• Technology and process innovation

• Logistics and delivery efficiency

• Informatization and digitalization

• Risk management and sustainable development

Quality

• AOI

• X-Ray inspection

• Impedance tester

• Flying probe tester

• Slice analysis

• SPI

• Reflow oven monitoring system

• IQC, IPQC, OQC

• Quality awareness training

•Professional skills training

Capacity equipment

• LDI, etching machine

• Mechanical and laser drilling

• Electroplating line

• Solder mask printing

• Spray tin, immersion gold, immersion tin, immersion silver

• Solder paste printing

• High-speed, multi-function patch

• Reflow soldering, wave soldering

• Rework and cleaning

• ERP/MES system,ESD protection

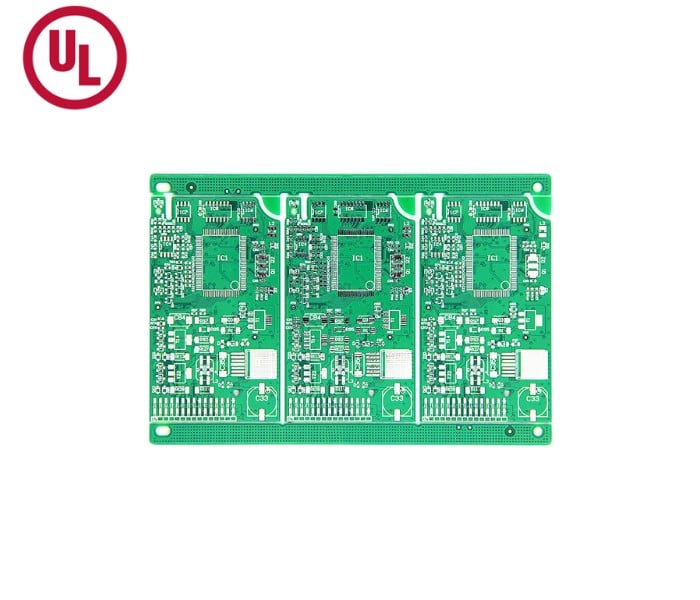

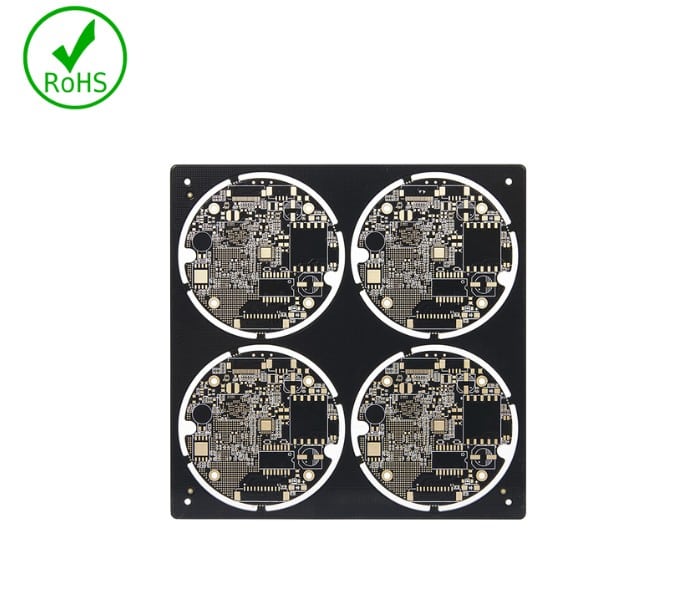

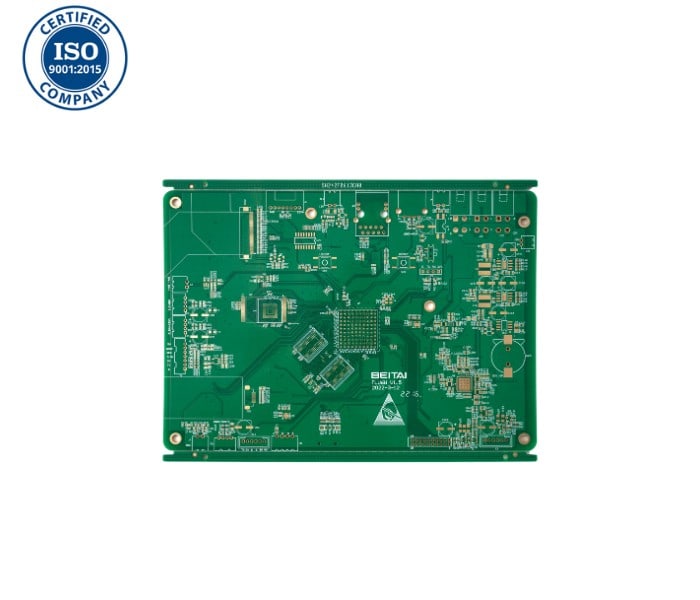

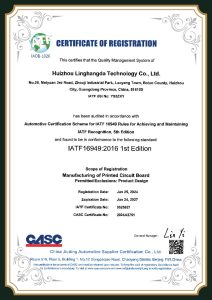

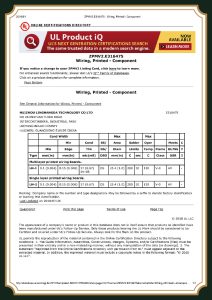

Qualification

• ISO 9000

• ISO 14000

• IATF 16949

• RoHS

• UL

• NPC

• FCC

Welcome to LHD TECH!

With over two decades of experience in the industry, our expertise covers one-stop solutions for PCBA projects including design, sourcing, assembly and testing provided by our dedicated team of professionals. Our approach is customer-centric and focused on building long-term relationships through personalized service and tailor-made solutions.

LHD Partner

After three years of cooperation with LHD TECH, the PCB manufacturing capacity exceeded expectations. What we value most is its control over details. The yield rate of HDI boards is stable at more than 99.2%, and the delivery time is 30% faster than that of local suppliers. The technical team can quickly respond to design optimization needs, truly achieving “one-stop service”.

Ja**s

We have high requirements for flexibility and speed from our suppliers. In our first order, LHD completed 100 sets of PCBA samples in just 72 hours and passed the ISO-9001 full inspection process. Their online order tracking system allows us to view production progress in real time, greatly reducing communication costs.

Gr**e

Since 2020, LHD has become our core supplier of automotive PCBs. Their automotive-grade boards (such as FR-4 TG170) fully comply with AEC-Q200 standards and provide complete IPC-6012 test reports. Even during the global chip shortage, they can ensure delivery stability through alternative solutions, which is truly trustworthy.

P**e

Contact With LHD TECH Today!

Company Service advantage

International certification: ISO13485, ISO9001, IATF16949, ISO14001, ISO45001, ISO13485, UL, ROHS

Fast Response & Delivery

We provide dedicated service with a mature order-to-cash process. Efficient management ensures fast delivery and customer satisfaction.

Environmental Responsibility

We comply with environmental regulations, use eco-friendly materials and processes, and maintain a perfect sewage treatment system.

Cost Optimization

We automate production and connect directly with factories, removing intermediaries. Our mature supply chain management reduces costs effectively.

Flexibility & Customization

We support large, medium, and small batch production with special materials and processes. Our dedicated technical team meets diverse needs.

Customer Service

Timely, accurate, and quality service is provided at every stage before, during, and after sales. Customer recognition builds our confidence.

Supply Chain Management

Our seven-step strategic procurement approach includes rigorous supplier assessment and partnership development to ensure supply stability.

Our Core Competencies

High-quality products are key to staying competitive. This includes the use of high-quality raw materials, precise manufacturing processes, and strict quality testing standards. Good quality control can reduce rework and improve customer satisfaction.

Continuous technological innovation capability is the key to maintaining long-term competitiveness. This may include the development of new manufacturing processes, the use of advanced production equipment, and the ability to handle more complex circuit designs.

Strong R&D capabilities not only drive technological innovation but also provide customized solutions to meet customers’ specific needs.

One-stop custom pcb manufacturer & PCB assembly manufacturer

Professional "Turnkey" Service

01

Design and layout

02

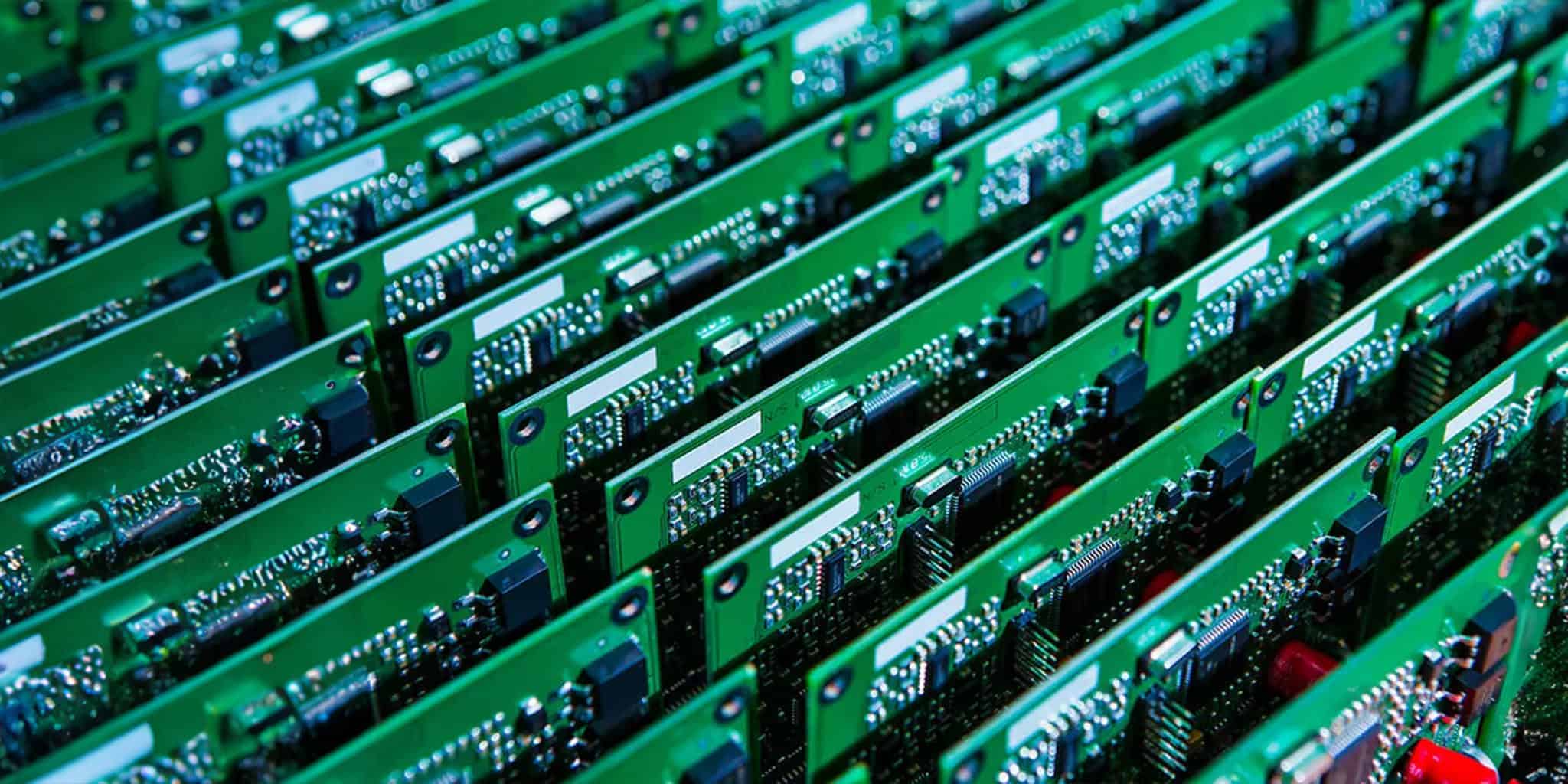

PCB Production

03

Parts Procurement

04

Assembly

05

Prototype

06

logistics and After-sales support

Electronic Manufacturing

Capacity

7 automated SMT production lines, 52 million mounts per month (0.15 seconds/chip, 0.7 seconds /QFP)

Equipment

Solder paste printer, SPI detector, automatic solder paste printer, 10-zone reflow, AOI, X-ray, baking machine, 3D printer, functional testing machine, coating protection

Specifications

Acceptable board sizes range from 0.25 "x0.25" to 680 X 500 mm

PCB Board Printing

Size

20,000 square meters, 500 employees, 24,000 square meters per month, $10 million per year

Product category

Rigid plate;Flexible plate;Metal plate; Soft and hard combination plate; High-density interconnection board; Radio frequency board; Onboard board

Plate material

FR-4 (Jiantao, Shengyi, Lianmao, South Asia, Taiguang Taiyao), high-frequency plate, Teflon plate, ceramic plate, Rogers, aluminum base, copper base, etc

Number of floors

1-68 floors

Max size

850*570mm

Equipment

Full line automatic production, complete environmental protection system equipment

PCB custom service

Custom PCB Manufacturer

At LHD PCB, we understand that every project has unique requirements. As a leading custom PCB manufacturer, we are committed to providing custom PCB solutions that perfectly match your specific needs. From flexible PCBs to rigid-flex and multilayer boards, we have the capabilities to design and manufacture the products you need. Our expert team works closely with you to ensure your specifications are met with the highest level of precision and quality. Let LHD PCB be your innovation partner.

PCB Solution

LHD PCB is not just a custom PCB manufacturer, we also have an R&D team that can provide PCB solutions. We offer comprehensive PCB services, from design assistance to after-sales support, ensuring you receive a comprehensive service for all your PCB requirements. Our expert team has cutting-edge technology and industry knowledge to provide you with innovative solutions that improve performance and reduce costs. Whether it’s a simple prototype or a complex PCB design, trust LHD PCB to provide you with an efficient, reliable, and effective solution.

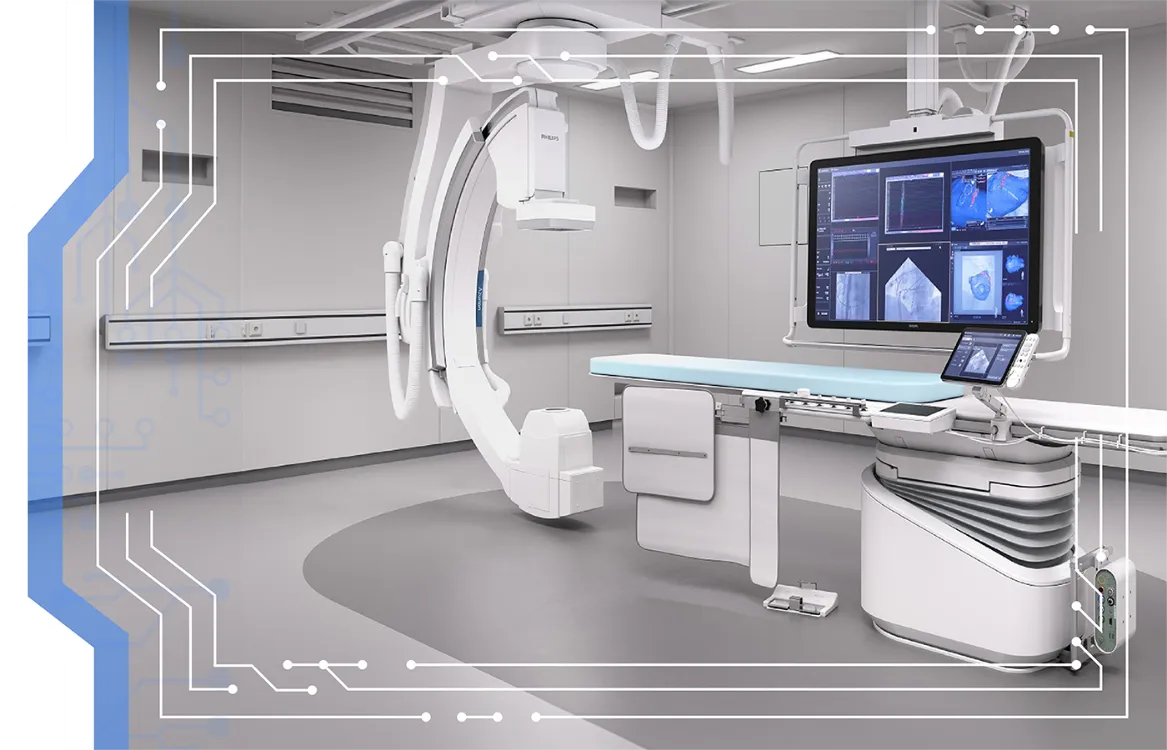

Applications

- Medical

- Security industry

- Household electrical

- Automobile industry

- Military industry

- Internet industry

Medical

The military industry field has extremely strict requirements for PCB and PCBA, and they need to be able to operate stably in extreme environments. PCB and PCBA are used in radar systems, communication equipment, navigation systems, weapon control systems, etc. In these applications, PCBs are not only required to be highly reliable and durable, but also need to be capable of high-density integration to accommodate the compact design of military equipment.

Security Industry

In the security industry, PCB and PCBA are the basis for realizing intelligent monitoring, alarm systems, access control systems, fire protection systems and other equipment. These systems rely on PCB to process images and data to achieve real-time monitoring, automatic alarm and remote control functions.

Household Electrical

In the Internet industry, especially in the context of the Internet of Things (loT), PCB and PCBA play the role of a bridge connecting various devices and the Internet. They are used in various smart home devices, environmental monitoring devices, smart wearable devices, etc., enabling these devices to collect data, process information, and communicate over the Internet.

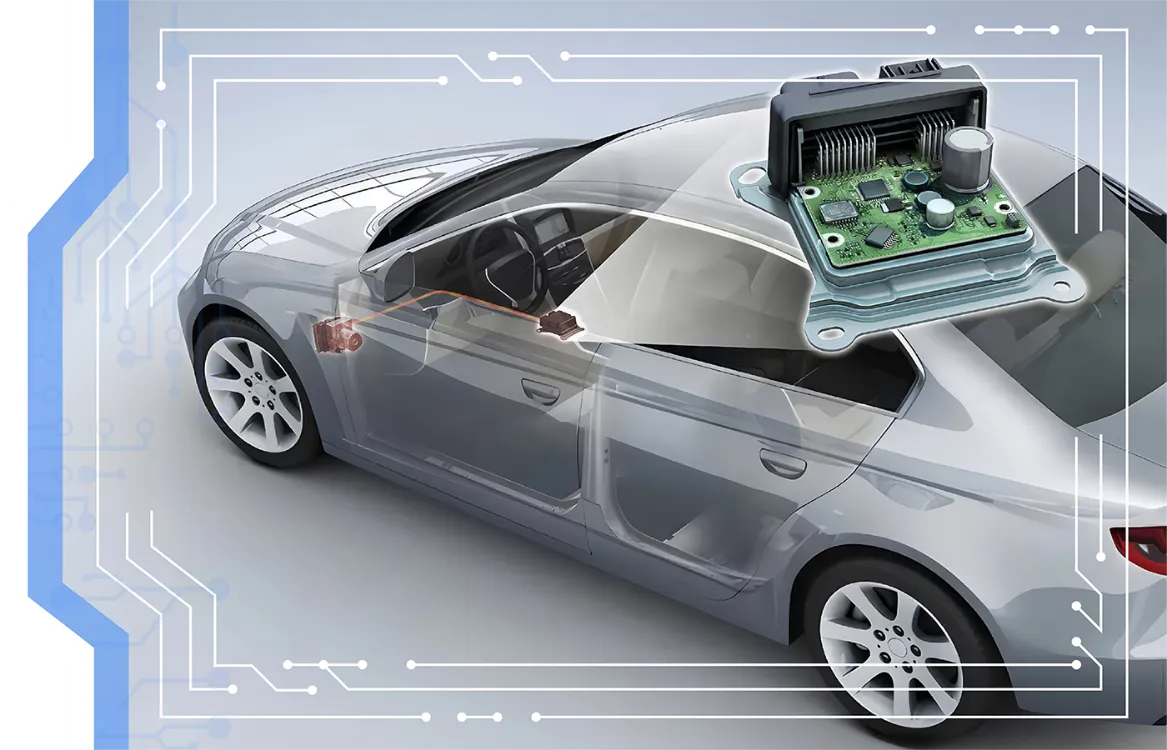

Automobile industry

In the automotive industry, with the development of electric vehicles and autonomous driving technology, the role of PCB and PCBA in automotive electronic syss has eom icsingly important. They are use in vehicle infotainment systems, navigation and GPS systems, safety and assisted driving systems (such as ABS and automatic braking systems), battery management systems, etc.

Military industry

The military industry field has extremely strict requirements for PCB and PCBA, and they need to be able to operate stably in extreme environments. PCB and PCBA are used in radar systems, communication equipment, navigation systems, weapon control systems, etc. In these applications, PCBs are not only required to be highly reliable and durable, but also need to be capable of high-density integration to accommodate the compact design of military equipment.

Internet industry

In the field of home appliances, PCB and PCBA are used to build electronic control systems for various devices, including refrigerators, washing machines, air conditioners, microwave ovens, etc. They enable devices to execute complex instructions, achieve automated and intelligent operations, and improve energy efficiency and user experience.

Enterprise's Goal

Improve production efficiency, reduce production costs, and maintain product quality.

Expand the market and serve global technology companies

Adhere to the concept of environmental protection, low carbon and energy saving, all products are environmentally friendly

corporate vision: To become the world’s outstanding one-stop PCBA manufacturer, serve customers from the most professional perspective and complete every commission with heart. Continuously innovate and develop continuously to become an enterprise that employees are proud of.

- Provide value to customers

- Create value for the company

- Allow yourself to give value