Need trustworthy PCB assembly services but intimidated by all the technical lingo and options? Don’t worry, you’re not the only one. Engineers and product designers often have trouble finding someone they can rely upon to deal with everything from prototypes through production without delay or surprise fees.

Whether you’re introducing a new product or are expanding a manufacturing line, the very last thing you want is substandard communication or subpar output. This article aims to keep things straightforward.

We’re here to take you through the real meaning of professional assembly of PCBs, how to choose the right service provider, and how an all-in-one solution can save time, money, and headaches.

Let’s get it started.

What Is PCB Assembly?

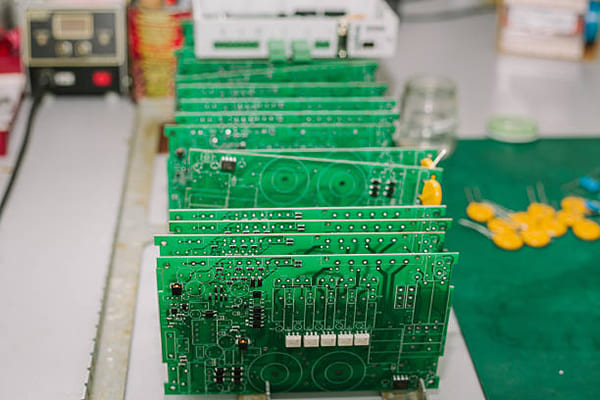

Printed Circuit Board Assembly, or PCBA, involves the task of affixing the electronic parts onto an empty PCB in order to have an operational electronic circuit. It should be noted that the PCB assembly services are not the same as those of manufacturing. While manufacturing makes the actual board—laminated with copper traces and holes—assembly makes the board functional.

PCB manufacturing can be described as constructing an empty house. Assembly, then, is when you put furniture into it, add appliances, and make it habitable.

A typical PCB assembly service would normally involve:

- Component positioning: This includes positioning different parts, such as resistors, capacitors, diodes, ICs, and connectors in their respective locations in the board.

- Soldering: These parts are soldered to the board with two principal methods:

- Surface Mount Technology, or SMT, where the component is mounted right onto the surface of the board

- Through-Hole Technology, or THT, where leads are inserted into holes and soldered

- Inspection & Testing: The last step is to examine and check the board for performance, through visual inspection, automated optical inspection (AOI, and in some cases, X-ray or function tests.

Whereas the PCB manufacturing assembly creates the canvas, the assembly stage is where your project takes shape and becomes reality, rendering it one of the most important product development stages.

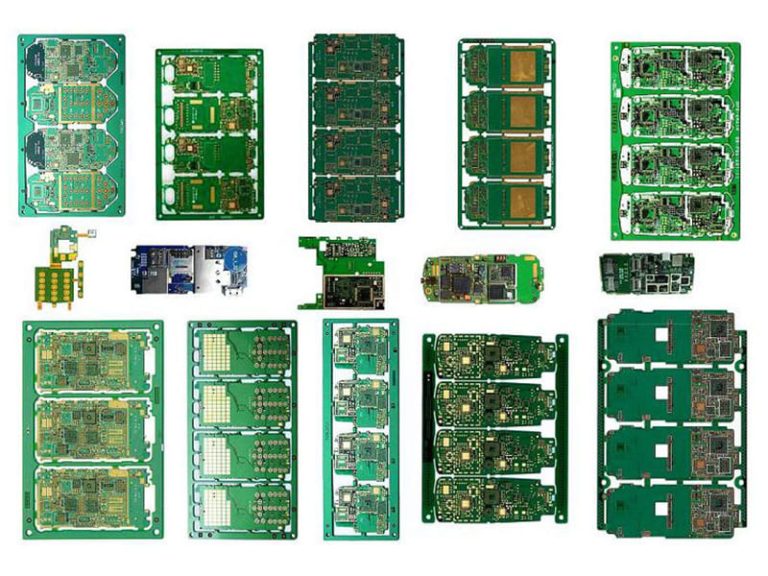

Types of PCB Assembly Services Offered

The right choice of PCB assembly services makes all the difference in the success of your electronics projects. Recognizing that each project is unlike the other, we at LHD-PCB are committed to providing your project with a series of tailored assembly services to suit your needs, with flexibility, efficiency, and quality at each step.

1. Turnkey PCB Assembly

Our turnkey assembly services are an end-to-end solution in which we take care of everything from component procurement and PC board fabrication to assembly and product testing. This is the best option for customers who want an effortless experience, wherein they can concentrate on product design and product innovation while we take care of production and logistics.

With more than 20+ years under our belts, we have built solid relationships with our component suppliers, allowing for prompt procurement and economic solutions. Utilizing our cutting-edge manufacturing plants, which house state-of-the-art machinery, we can deal with intricate assemblies accurately and with high efficiency. Through our turnkey service, customers enjoy improved communication, shortened lead times, and even quality control throughout the production chain.

2. Consigned PCB Assembly

For customers who want to provide their own parts, our consignment PCB assembly service is available to do so. With this arrangement, you supply the parts needed, and we take care of the assembly, making sure each part goes where it belongs and is soldered as agreed upon.

This method is especially valuable for customers who need customized ordering or have already sourced parts. Our skilled technicians use high-end assembly methods, such as Surface Mount Technology (SMT) and Through-Hole Technology (THT), to guarantee high-grade output. Moreover, our strict quality control measures, such as Automated Optical Inspection (AOI) and functional testing, ensure that the assembled PCBs are up to your performance standards.

3. Partial Turnkey Assembly

Our partial turnkey assembly solution integrates the best of both turnkey and consignment models. Clients are able to supply certain parts, while we procure the rest of the parts and do the assembly. This model offers more control over certain parts while realizing the procurement value and manufacturing skills offered by us.

This option is best suited for jobs where there are proprietary or purchased parts, but the client still wants to take advantage of our services for the remainder of the assembly. When working closely with our clients, we ensure smooth integration of the parts provided and sourced, with uniformity and quality throughout the assembly. Flexibility and customer satisfaction are assured with partial turnkey assembly, which is why it is among our clients’ favorites.

4. PCB Assembly Prototype Service

Prior to shifting to mass production, validating your design through prototyping is critical. Through our PCB assembly prototype solution, we aim to deliver prompt and precise prototypes, allowing clients to effectively test and perfect their designs.

Our expertise at LHD-PCB lies in quick prototyping, with minimal turnaround times while ensuring high quality. Our prototyping services cover different types of PCBs, such as rigid, flexible, and rigid-flex boards, and support different applications. Through state-of-the-art methods of assembly and rigorous testing procedures, we ensure that the prototype represents the performance of the end product accurately. This is an indispensable service when identifying problems at an early phase of the developmental stage, ensuring time and cost savings in the future.

All of these pc board assembly services are customized to address unique project needs, with flexibility, efficiency, and quality in mind. At LHD-PCB, we aim to offer complete solutions that help our clients throughout the product’s lifecycle.

PCB Assembly Process: Step-by-Step

Professional assembly of PCBs is dependent upon an organized, accurate process. For LHD-PCB, our assembly process is designed around quality control and scalability:

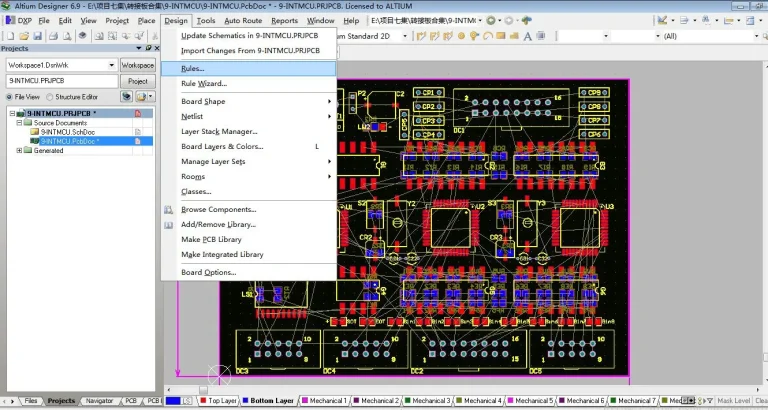

1. Design File Submission

We produce Gerber files, BOM (Bill of Materials), centroid data, and assembly drawings. These are checked, and we mark any issues.

2. Component Sourcing

For partial-turnkey and turnkey projects, we procure parts from official distributors. We verify availability, authenticity, and quality.

3. Solder Paste Application

A stencil is utilized to place solder paste precisely on the pads of the PCB. This is necessary to guarantee proper component positioning.

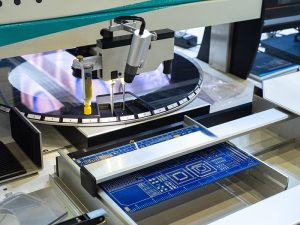

4. Pick and Place

SMD components are mounted automatically on the board. This precision helps to create the right electrical contacts and mechanical stability.

5. Reflow Soldering

The board is then run through a reflow oven, where the solder paste is melted and the parts are soldered onto the board.

6. Through-Hole Component Insertion

For mixed technology boards, through-hole parts are inserted manually or semi-automatically, then wave soldered or hand soldered.

7. Inspection and Testing

AOI (Automated Optical Inspection): Identifies misalignment, missing parts, or solder defects

X-ray Inspection: For BGAs and fine-pitch parts

ICT/Functional Testing: Validates that the board functions as expected

8. Cleaning and Packaging

Boards are cleaned to remove the residue of the flux and subsequently packaged with anti-static materials for safe transport.

By streamlining this procedure, our PCB assembly services provide high quality, consistency, and quicker delivery.

Benefits of a One-Stop PCB Assembly Provider

In selecting your PCBA solutions provider, selecting a one-stop solution such as LHD-PCB presents many benefits. Having your PCBA fabrication, component procurement, assembly, and testing all under one roof simplifies your manufacturing flow and offers many benefits to businesses of all sizes.

Let’s explore the advantages of selecting a one-stop PCBA solutions provider in a little more detail:

1. Reduced Lead Time

Reduced lead time is one of the greatest benefits of working with an all-inclusive PCB assembly provider. When all of the stages of production, right from manufacturing the PCBs to acquiring the component parts and putting them together, are dealt with by a single team, there is no time-wasting coordination with various vendors.

We have the whole process in-house at LHD-PCB, which reduces the delays caused when there are various suppliers involved at several stages. Your prototypes and finished products are delivered faster, which is just right for businesses that have to have their products out soon in the marketplace. Whether you are producing one prototype or large-volume production, our streamlined process guarantees your project goes through each phase quickly, minimizing unnecessary waiting times and speeding your time-to-market.

2. Quality Assurance

Consistency and quality are the very essence of each PCB project, and this is where the one-stop PCB assembly company excels. Having all services under one roof means that each phase of the manufacturing process can be closely monitored.

In our manufacturing plant at LHD-PCB, our quality control systems are ISO-certified, which monitor each step of the manufacturing process, starting from component procurement right through the soldering and testing. Such a high degree of control guarantees that each piece meets high standards of quality and performance. Whether you have low-volume prototypes or high-volume production, our team of quality control personnel performs continuous inspection to ensure mistakes are prevented and uniformity is achieved on all programs. By entrusting us with your order, you can be assured that your PCB assembly will possess the highest standards of quality.

3. Cost Efficiency

Bundling all of the services you need under one umbrella package isn’t just more cost-effective—it’s more efficient. When you deal with an all-inclusive provider like LHD-PCB, you save yourself the expense of having to use multiple suppliers for your project.

By handling PCB assembly internally, we’re able to provide competitive prices without sacrificing quality. For higher volume or recurring work, this cost-effectiveness becomes even more dramatic. The convenience of combining design, assembly, and testing into one package keeps administrative overhead and logistics costs to a bare minimum. On top of that, our relationship with our component suppliers enables us to negotiate improved material prices, further reducing your project cost. This leaves you free to concentrate on your business while we take care of the cost-effective delivery of your PCB assembly.

4. Enhanced Communication

Smooth, effective communication is key in any project, particularly in the field of PCB assembly. When you have a one-stop provider, communication becomes much more streamlined, minimizing the risk of errors or miscommunication. Rather than handling several points of contact with different vendors, you have one person who manages all areas of the project.

With us at LHD-PCB, you get direct communication with your own project manager, who coordinates the entirety of your PCB assembly services from initial contact to finished product. This direct communication guarantees fast decision-making, quick responses to technical questions, project progress, and scope changes, preventing misunderstandings and ensuring an efficient overall experience, which benefits both your timeline and budget.

5. Scalability

One of the special benefits of using a one-stop PCBA provider is being able to scale your manufacturing without needing to switch vendors. If you are an enterprise with thousands of units needed or just a startup with a single one-off prototype, we can support both ends.

We are capable of handling both high and low-volume manufacturing, allowing your growth to be well-supported at each stage. When your business grows, you will not need to endure the inconvenience of switching to a new provider or altering your supply chain. With our adaptability, you can ramp up production volumes effortlessly, from prototypes or small batches to high-volume production. This flexibility guarantees that your PCB assembly capabilities can respond to your growing needs, making you responsive and competitive in the market.

Regardless of whether you are just starting out with one board or have thousands of units with an enterprise, our single-source pc board assembly model keeps your firm nimble and competitive.

Industries Using PCB Assembly Services

Our customers range from a broad spectrum of industries. These are the areas where our PCB manufacturing assembly solutions are creating an impact:

Consumer Electronics: Smartphones, wearable technology, smart home appliances

Medical Devices: Portable diagnostic devices, patient monitoring devices, biosensors

Equipment Industrial: Automation systems, PLCS, control panels

Telecommunication: Routers, modems, base stations

Automotive electronics: EV controllers, ADAS systems, lighting control

Every industry has differing compliance and performance needs. We develop our processes to maintain regulatory compliance and product integrity with each application.

Why Choose LHD-PCB for PCB Assembly Services?

LHD-PCB is not only another supplier but your long-term technology partner. This is why:

- Full-Service Capability: from bare board manufacturing to finished assembly and testing

- Fast Prototyping: Require it tomorrow? We do prototype delivery in just 24–72 hours.

- Global Distribution: We export to over 50 nations with specialized delivery support

- Trained Staff: IPC-certified technicians and engineers

- Custom Engineering Support: Design-for-Manufacturing (DFM) evaluations, alternative component suggestions, and layout recommendations

- Transparent Prices: Immediate quotes, with no hidden charges

Our dedication to quality and our efficiency make us the go-to option for businesses worldwide seeking one-stop pc board assembly services that they can trust.

Conclusion

The need for increased speed, miniaturization, and processing power in electronics keeps expanding, and so does the demand for reliable PCB assembly services. With over three decades of experience, state-of-the-art infrastructure, and an unrelenting pursuit of quality, LHD-PCB is your leading partner for everything from prototype to high-volume production.

Be it the need for a PCB assembly prototype service to prove an idea or an authentic vendor for high-volume PCB assembly, we’re here to do it.